SBI-191 VISUAL FAULT LOCATOR

Price 13999 INR/ Piece

SBI-191 VISUAL FAULT LOCATOR Specification

- Mounting Type

- Handheld

- Size

- Pen Type

- Range

- 5 km (approx.)

- Connectivity Type

- Fiber Optic Connection

- Power Supply

- 2 x AA Batteries

- Model

- SBI-191

- Features

- Handheld, Portable, Durable, Easy to Use

- Interface Type

- 2.5 mm Universal Connector

- Operating Temperature

- -10C to +60C

- Battery Backup

- 8-10 Hours

- Product Type

- SBI-191

- Application

- Commercial & Industrial

- Dimension (L*W*H)

- 170 mm x 26 mm

- Material

- Plastic

- Weight

- 2 Kilograms (kg)

- Capacity

- 1 pc

- Coverage Area

- Up to 5 km (typical, depending on fiber quality)

- Wavelength

- 650 nm (Visible Red Light)

- Pulse Mode

- CW & Modulation (Pulsed)

- End Connector

- 2.5 mm for LC/SC/ST/FC type

- Laser Safety Class

- Class II

- Body Color

- Red-Black

- Package Contents

- Device, User Manual, Batteries

- Detection Type

- Fiber Breaks, Bends, Fault Locations

- Output Power

- <1 mW or <5 mW (model options)

SBI-191 VISUAL FAULT LOCATOR Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About SBI-191 VISUAL FAULT LOCATOR

Made of high quality aluminum material.Portable,durable and rugged, easy to use, 2.5mm & 1.25mm for SC,ST,FC and LC Connectors Strong light source, strong Penetrating power, stable property. And have two mode: always light and flicker. Constant output power, lower Battery warning, Long battery life (up to 60 hours) It is resent from slipping, comfort grab feel, carefully modified. Crash-proof and dust-proof design for its pen head Easy to change the ceramic core. It will help to extend the use of time

Efficient Fiber Fault Detection

Pinpoint fiber optic breaks, bends, and faulty locations quickly with the SBI-191 Visual Fault Locator's visible red laser. Its powerful detection capabilities, combined with both continuous and pulse modes, make troubleshooting faster and more accurate in various fiber networks.

Designed for Professional Environments

Constructed with durability and convenience in mind, the handheld SBI-191 is built for commercial and industrial settings in India. Its universal connector supports multiple fiber types, and its lightweight, easy-to-handle design allows for extended usage without fatigue.

Long Battery Life, Ready Anywhere

Powered by two AA batteries, the SBI-191 delivers an impressive 8-10 hours of operation. Its portable form ensures it's always ready for use, whether on-site or in the field, with the ability to cover up to 5 kilometers depending on fiber quality.

FAQ's of SBI-191 VISUAL FAULT LOCATOR:

Q: How do I operate the SBI-191 Visual Fault Locator?

A: To use the SBI-191, insert two AA batteries, connect the device via its 2.5 mm universal connector to your fiber optic cable (compatible with LC, SC, ST, or FC types), and select either continuous wave or modulated (pulsed) mode. The visible red laser will then help you identify breaks and faults along the fiber.Q: What are the benefits of using a Visual Fault Locator with 650 nm wavelength and Class II laser safety?

A: A 650 nm visible red light offers high visibility for easy fault detection. Combined with Class II laser safety, the SBI-191 ensures effective performance without compromising user safety, making it a reliable choice for both commercial and industrial use.Q: When should I use the Visual Fault Locator's CW or Pulse mode?

A: Continuous Wave (CW) mode is ideal for quickly identifying main breaks or severe faults along the fiber, whereas modulation (Pulsed) mode is helpful for locating minor breaks, sensitive bends, or faults in environments with ambient light distractions.Q: Where can the SBI-191 be used and what types of fiber connectors does it support?

A: The SBI-191 is optimized for both commercial and industrial environments across India, supporting LC, SC, ST, and FC fiber connectors via its 2.5 mm universal interface, making it suitable for a wide variety of fiber network setups.Q: What is the maximum fiber length the SBI-191 can effectively test?

A: The device can typically detect faults up to 5 kilometers along the fiber, depending on factors like fiber quality and type, making it suitable for most in-building and certain campus network applications.Q: What are the package contents and power requirements for the SBI-191?

A: Each SBI-191 package includes the visual fault locator device, a user manual, and two AA batteries. These batteries provide a robust 8-10 hour operational backup, ensuring extended use in the field.Q: How does the SBI-191 enhance the process of fiber optic maintenance?

A: By allowing technicians to rapidly pinpoint and visibly identify the location of faults, breaks, or sharp bends, the SBI-191 streamlines fiber maintenance and minimizes downtime, ensuring more reliable network performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Test Equipment Category

VF-10 Visual Fault Locator

Price 12999 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Commercial & Industrial

Material : Plastic

Battery Backup : Up to 40 hours

Operating Temperature : 10C to +50C

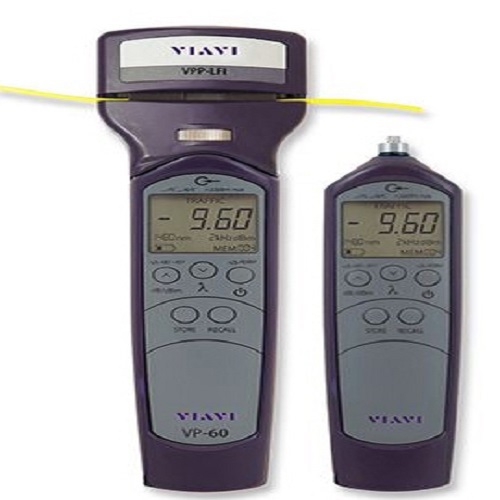

FI-60 JDSU Optical Power Meter

Price 23999 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Commercial & Industrial

Material : Plastic

Battery Backup : 8 hours continuous use

Operating Temperature : 10C to +50C

SBI-520 OPTICAL POWER METER

Price 15999 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Commercial & Industrial

Material : Plastic

Battery Backup : Rechargeable Liion, up to 20 hours

Operating Temperature : 10C to +60C

Power Supply 2 amp

Price 399 INR / Piece

Minimum Order Quantity : 10 Pieces

Application : Commercial & Industrial

Material : Metal

Battery Backup : No

Operating Temperature : 0C to 40C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry